Bühler and Entocycle align to reduce time to market for companies building insect facilities

The partners will provide solutions and expertise to serve customers in this segment, covering concept and basic engineering to execution of BSF facilities worldwide. Entocycle will deliver proprietary breeding technology while Bühler has proven industrial-scale technologies in feedstock processing, larvae rearing, and product processing.

One of the challenges of the highly promising, emerging insect industry, they noted, has been how to ensure a steady supply of young larvae at an industrial scale.

"Although there are specialized breeding service companies in certain regions, in large parts of the world, there is no alternative to having an in-house breeding operation. With this partnership, Bühler and Entocycle address this challenge by offering scalable end-to-end solutions that significantly reduce the time to market for companies building an insect facility."

Matthew Simmonds, managing director, Entocycle, talked to FeedNavigator about how this partnership will achieve that goal:

“The early movers in the insect protein industry have had to develop their own in-house systems and processes, often through lengthy trial and error. Bühler and Entocycle have developed their leading technology and expertise after nearly a decade of research and development. The partnership brings together two significant strengths from different domains. Bühler's experience and reputation for managing large-scale and intricate engineering projects, combined with Entocycle's specialized expertise in breeding black soldier flies, result in a comprehensive solution that covers all aspects of establishing and operating a BSF facility and serves as a streamlined expressway to establishing successful BSF facilities.

“Now, customers can come to the experts in the industry to purchase complete BSF farm solutions. The synergy between Bühler and Entocycle translates into expedited processes, reduced timelines, and quicker realization of returns on investment for businesses entering the insect farming sector.

“Our partnership's unified approach ensures that customers can swiftly move from concept to operational production, providing a substantial competitive advantage in a dynamic industry.”

Counting and dosing

Entocycle’s flagship product, Entosight Neo, continued Simmonds, addresses one of the biggest problems in the industry, which is inaccurate counting and dosing of larvae. It is a software and hardware package based upon an optical sensor that monitors and collects data on the health and productivity of a BSF colony.

The technology is designed to reduce the need for manual human processes such as weighing larvae, multi-step handling and inaccurate counting to result in higher-feed conversion rates, lower mortality, and larger insects on farms.

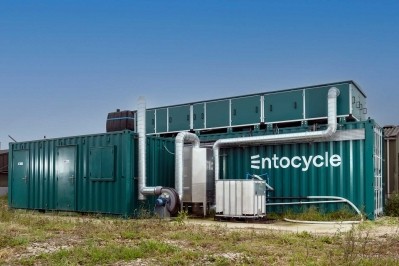

Entocycle also manufactures and supplies fly rooms as a complete turnkey breeding solution designed to achieve optimal BSF breeding efficiencies and the highest possible egg yields.

Lowering market entry hurdles

During the past 10 years, Bühler has been developing its capabilities in the insect protein industry and has already completed a number of relevant projects in the field. In 2019, it supported Protix in the realization of the world’s first commercial BSF facility in the Netherlands and this year saw it make Agronutris' first industrial BSF production plant a reality - that unit is located in France.

“The industrial use of BSF is rapidly gaining traction among businesses seeking alternative feed protein sources and more sustainable practices. To accelerate scaling this industry we must contribute to lowering the hurdles for companies to enter this business,” said Andreas Baumann, head of market segment, insect technology, Bühler.

In terms of what countries this alliance will target, Simmonds said the two entities were focused on deploying industrial-scale facilities in Europe, North America, and Oceania. “These markets make the most commercial sense for us currently.”